Located in Marnaz, in Haute-Savoie, our DSMP factory has a state-of-the-art machine park, capable of meeting a variety of needs, ranging from prototypes to large series. Specialising in the machining of engineering plastics such as PTFE, POM, PEEK, PCTFE, PA6/6, PVC, PVDF and PEI, we produce a wide range of components. Our equipment can be used to manufacture insulators for connectors, medical components, sealing systems and domestic parts (screws, nuts, spacers and small plastic parts machined to plan).

Our regularly serviced and upgraded machines ensure flexible and precise production that strictly adheres to our quality policy. Whether for small batches or larger production runs, our high-performance equipment ensures consistent quality and responsiveness tailored to our customers’ needs.

DSMP is equipped with 10 latest generation Citizen CNC machines, specially designed for the production of small and medium series. These state-of-the-art 7-axis machines and more offer great precision and flexibility, suitable for machining technical plastics such as PTFE, POM, PEEK, and many others.

Equipped with automatic bar feeders, high-pressure pumps, and the LFV system for chip segmentation, our digital machines guarantee rapid production cycles while minimizing material loss. This advanced technology enables the production of complex parts with tight tolerances, meeting the requirements of the medical, connector, and fluid and gas sealing sectors.

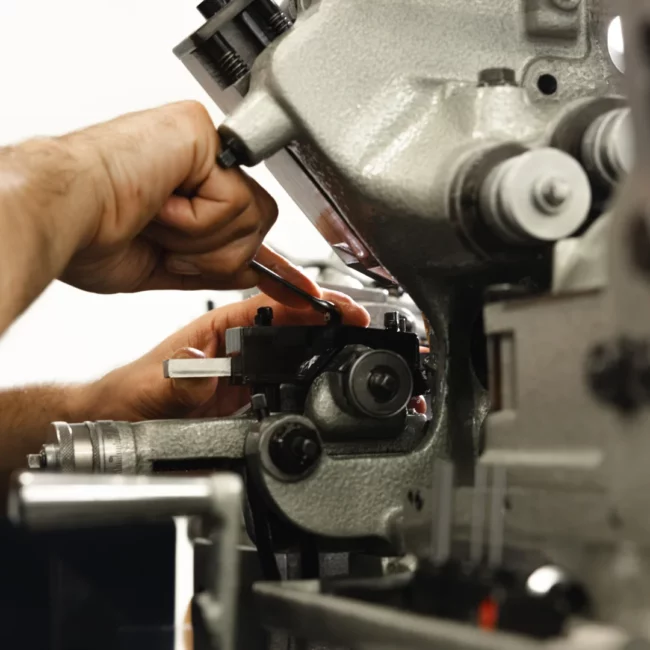

Our machine park also includes 20 traditional cam lathes from the Tornos brand, recognized for their efficiency and productivity. These machines are dedicated to the production of small and large series, and are perfectly suited to the manufacture of standardized plastic parts such as seals, washers and axles.

Although more traditional, our cam-operated lathes are regularly optimized to maintain impeccable production quality. Their mechanical simplicity and speed of execution make them an ideal choice for large-scale production, while ensuring consistent precision.