-

DSMP Marnaz

High-precision plastic turning

Founded in 2004, DSMP specializes in the turning and machining of technical plastics. With a skilled team and high-performance machinery, DSMP offers high-quality machined parts with flexibility and responsiveness.

Founded in 2004, DSMP specializes in the turning and machining of technical plastics. With a skilled team and high-performance machinery, DSMP offers high-quality machined parts with flexibility and responsiveness.

-

Solutions

on planFrom prototype to large series

DSMP in Marnaz uses state-of-the-art machinery to produce a variety of components for connectors, medical equipments, waterproofing, and household appliances. Thanks to its regularly upgraded equipment, DSMP guarantees flexible and precise production.

DSMP in Marnaz uses state-of-the-art machinery to produce a variety of components for connectors, medical equipments, waterproofing, and household appliances. Thanks to its regularly upgraded equipment, DSMP guarantees flexible and precise production.

DSMP Marnaz

20 years of expertise in plastic turning

Founded in 2004 by Stéphane Dunoyer, DSMP specializes in the turning and machining of technical plastics (PTFE, POM, PEEK, etc.). Thanks to our expertise and high-performance machinery, we produce parts from 0.1 to 38mm in diameter, from prototypes to large series.

Our ISO 9001 certification and our commitment to quality guarantee tailor-made, precise and reliable parts. Today, 20 years after its founding, DSMP continues its development with cutting-edge equipment and a vision focused on innovation.

Expertise Areas

Connector insulators

DSMP manufactures PTFE and PEEK insulators for coaxial and multi-contact connectors used in the industrial, military, space, and nuclear sectors.

Precision mechanics

We produce custom turned plastic parts (screws, nuts, fittings, axles) for aeronautics, industry and consumer goods.

Medical equipments

DSMP manufactures plastic components for medical, dental, and veterinary equipment, including implantable parts and precision devices.

Sealing components

Our PCTFE, PTFE, and PEEK parts ensure optimal sealing in gas systems, valves and medical or industrial applications.

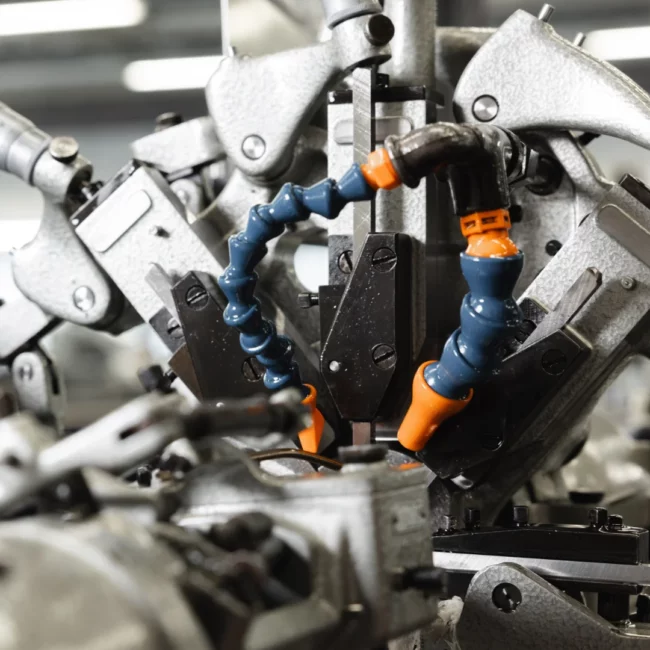

Modern and efficient

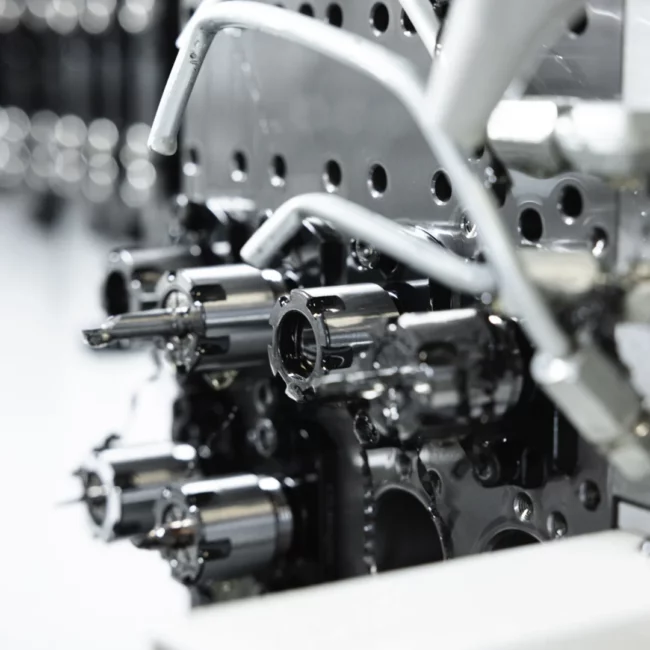

DSMP has a machine park capable of responding to all types of requests, from prototypes to large series. Specializing in the turning of technical plastics (PTFE, POM, PEEK, etc.), the company manufactures components for various sectors : connectors, medical, sealing and industrial technical parts.

Our equipment, regularly serviced and upgraded, guarantees flexibility, precision, and consistent quality, regardless of production volume. Thanks to this comprehensive and efficient machine park, DSMP adapts to the specific needs of each client and guarantees reliable, responsive, and competitive production.

Precision and flexibility

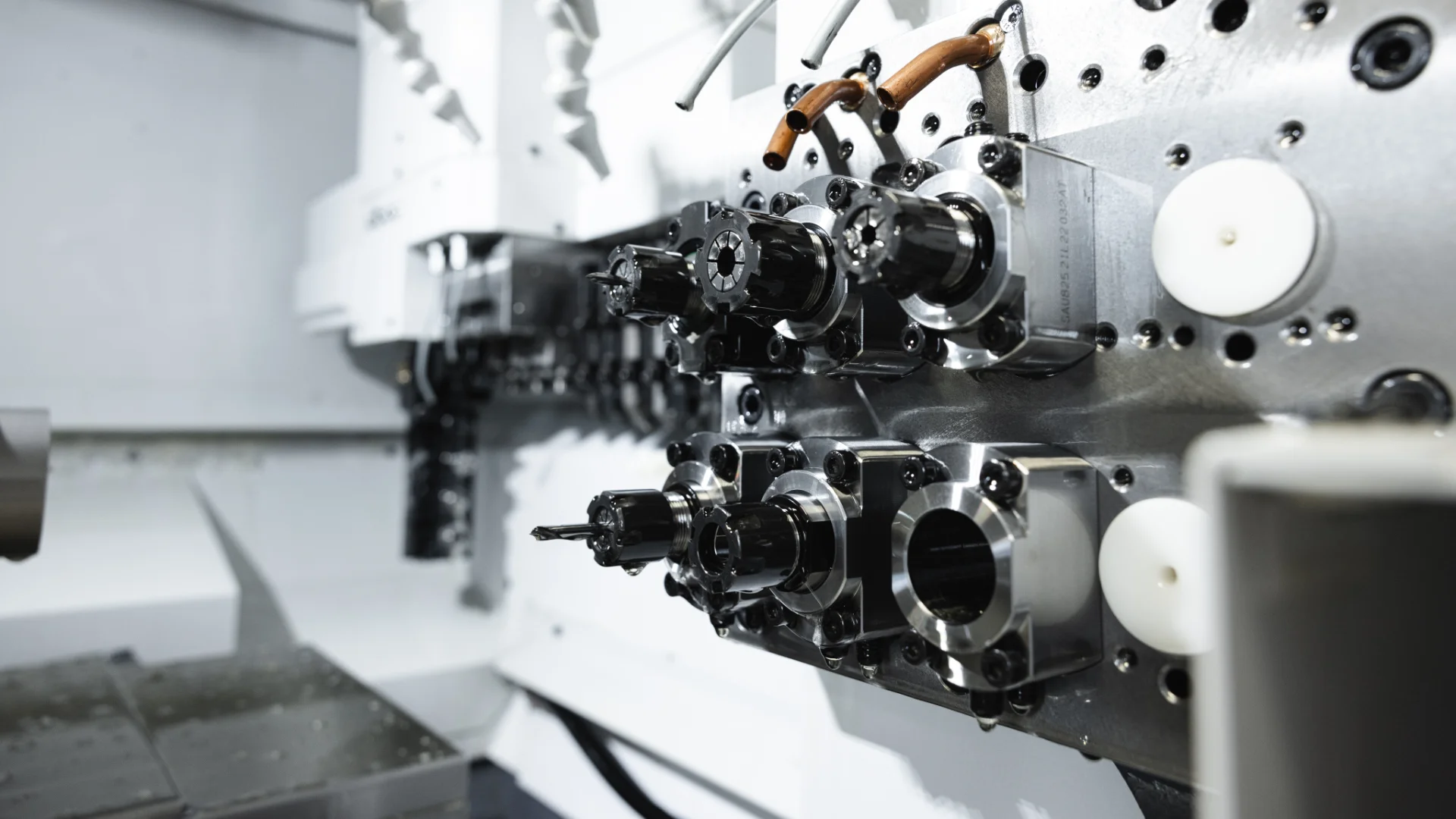

DSMP is equipped with 10 Citizen CNC lathes with sliding headstock, optimized for small and medium series. These 7-axis machines and more, equipped with automatic bar feeders, high-pressure pumps, and the LFV system (chip segmentation), ensure high precision, reduce material loss, and enable optimized production cycles. They are ideal for manufacturing complex parts for the medical, connector, fluid and gas sealing sectors.

Robustness and Efficiency

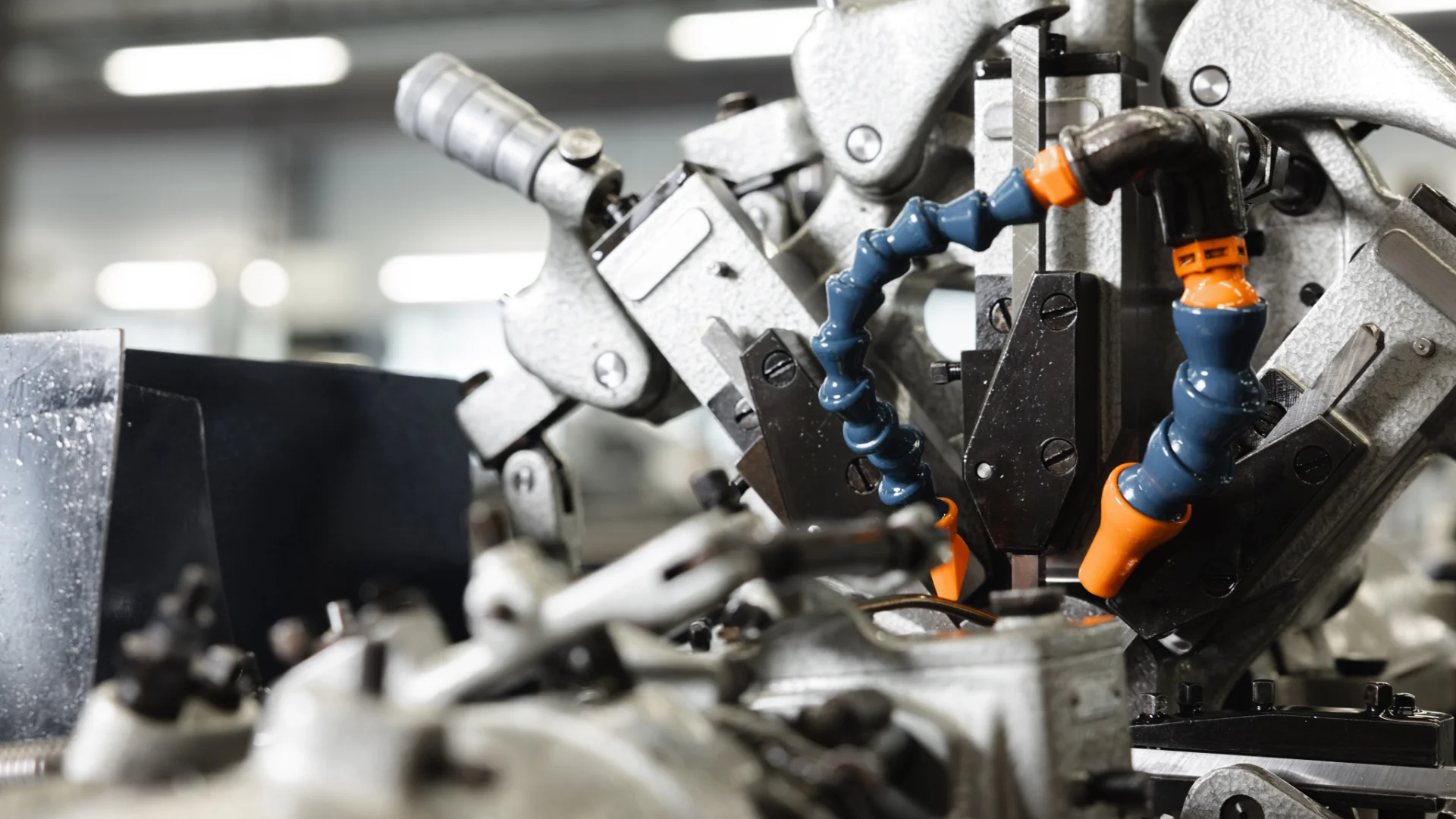

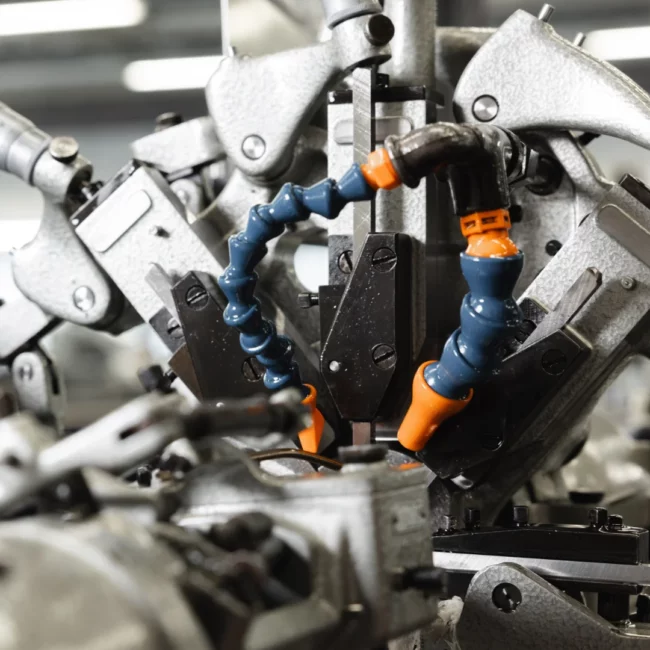

Our workshop also includes 20 traditional lathes with sliding headstock from the brand Tornos, dedicated to small and large production runs. Particularly suited to standardized parts such as screws, nuts, and spacers, this equipment combines rapid execution with production stability. Regularly optimized, they guarantee impeccable quality while offering an economical solution for large-scale production.

Who says size doesn't matter? At DSMP, we push the limits of precision plastic machining every day. This month, we are highlighting an exceptional piece: a miniature component in PEEK

DSMP places quality, rigor, and responsiveness at the heart of its development. In a process of continuous improvement, we optimize product quality, responsiveness and cost control to guarantee customer satisfaction.

Our quality policy is based on structured management, supervised by Ms. Morgado Alexandra, and a process of continuous improvement to ensure the sustainability of the company.

ISO 9001 certified, DSMP is committed to providing high-precision machined parts that meet international standards and customer requirements.